Double-glazed cleanroom windows

Sealed design

Thermal insulation

Excellent visibility

Ease of cleaning

Guaranteed sterility

Product description

Double pane cleanroom windows are carefully designed to meet the stringent requirements of controlled areas. Their exceptional tightness, achieved through a sealed frame and double-layer construction, ensures complete isolation of the clean room from external contaminants. This is especially important in sterile manufacturing areas, such as medical device manufacturing, where maintaining clean air is critical. The insulating properties of double-pane glass help stabilize room temperatures, reducing heating or cooling energy consumption and preventing condensation that can compromise cleanliness. These characteristics make windows ideal for biotechnology and other temperature-sensitive applications.

Thanks to Low-E glass, the windows provide high optical clarity, providing clear visibility for monitoring critical processes. Their smooth, durable surfaces are easy to clean and disinfect, meeting the stringent hygiene requirements of cleanrooms such as food processing facilities.

These modern windows are an essential component of cleanrooms, providing productivity, energy efficiency and sterility control while meeting the highest industry standards.

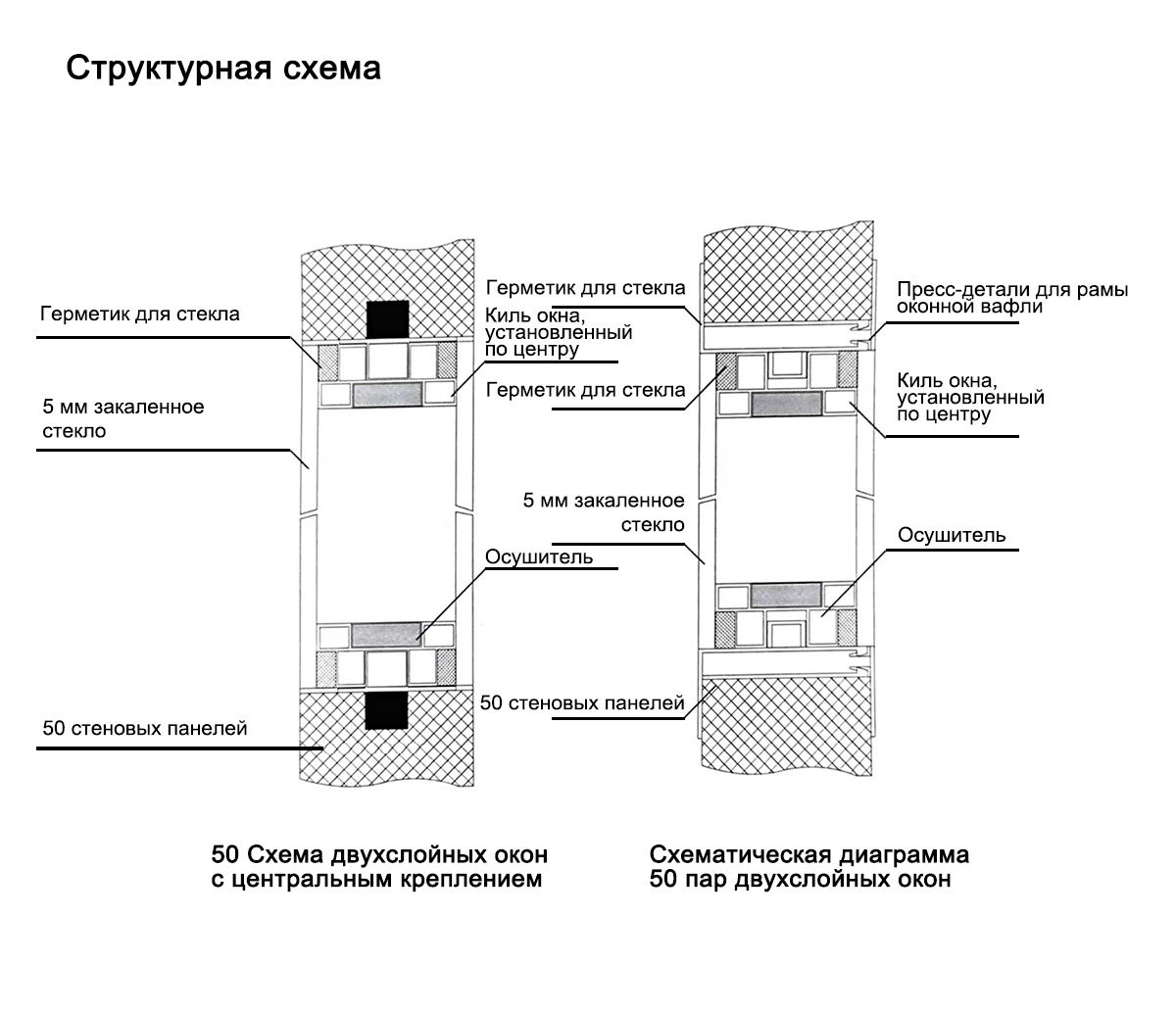

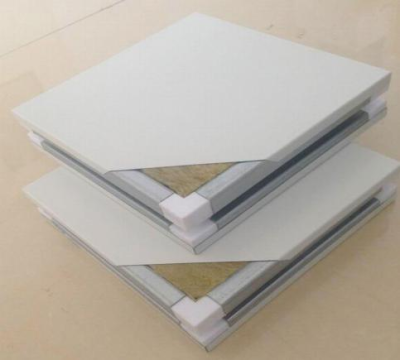

Composition and structure

Double-pane cleanroom windows consist essentially of two panes of glass separated by an air gap. The glass used is usually high quality low-emissivity (Low-E) glass. This type of glass has a special coating that allows visible light to pass through while minimizing the transfer of heat and ultraviolet radiation. For example, in a semiconductor manufacturing cleanroom where temperature and lighting control are critical, Low-E glass helps maintain stable internal temperatures and protects sensitive equipment from harmful UV rays. The window frame is usually made of aluminum alloy. Aluminum alloy has excellent corrosion resistance, high strength and durability.

It is also easy to process and install, making it a preferred choice for cleanroom window frames. The frame is precision engineered to ensure a tight fit around the glass panels. Gaskets made of rubber or silicone are often used to prevent air leakage and the entry of dust, particles and contaminants. In a pharmaceutical cleanroom, even a small gap or leak in a window frame can compromise the sterility of the environment.

Areas of application

Semiconductor and Electronics Industry: Cleanrooms where chips and other electronic components are manufactured use double-pane windows to separate different processing areas. They allow engineers and technicians to monitor the production process while maintaining the required clean environment. Sealing and thermal insulation properties are critical to protecting sensitive electronic equipment from temperature extremes and contamination.

Pharmaceutical and Biotech Industry: From dosage formulation development to cell culture laboratories, these windows play a key role. In a pharmaceutical cleanroom used for sterile packaging of drugs, a window provides a visual connection between the packaging area and the quality control area, ensuring sterility of the product. In a biotech cleanroom where gene-editing experiments are carried out, a window allows researchers to view the experiments in progress without the risk of introducing contaminants.

Medical Device Manufacturing: Cleanrooms dedicated to the production of surgical instruments or implantable devices use double-pane cleanroom windows to keep the manufacturing process clean and safe. The window allows you to separate the machining area from the inspection area, providing effective quality control.

Maintenance and Precautions

Regular Cleaning: The window surface should be cleaned regularly using approved cleanroom cleaning products. This applies to both glass panels and frames. The cleaning process must be carried out in a controlled manner to avoid reintroduction of contaminants. For example, in a cleanroom used for vaccine production, any uncleaned tools or cleaning methods may contain bacteria or viruses that can contaminate the window and the environment.

Inspect Seals and Glass: Periodically inspect seals for signs of wear, damage, or looseness.

Also inspect the glass for cracks or chips. If problems are found, they should be repaired or replaced immediately. In a high-tech cleanroom where window integrity is critical to a successful manufacturing process, even a small leak or crack can have serious consequences.

Temperature and Humidity Control:

Although the window itself has insulating properties, it is still necessary to maintain appropriate temperature and humidity levels in the clean room. Excessive fluctuations in temperature or humidity can cause condensation to form on the surface of the window or affect the performance of the seals. This is especially important in optical manufacturing cleanrooms where precise temperature and humidity control is required to ensure the quality of optical products.

Technical Parameters

| Cleanroom window options | |||||

| General dimensions | Thickness | Frame | Glass | Sealing | Notes |

| 1.2*1.5 m | Adaptable to walls made of sandwich panels 50–100 mm thick | Stainless steel/aluminum alloy | Tempered glass 5 mm | Rubber band/silicone | Available upon individual request |

| 1.2*1.8 m | |||||

| 1.5*2m | |||||

| 1.5*2.4 m | |||||

| Custom size | |||||