Sandwich Panels With Mineral Wool

Thermal insulation:Stone wool provides excellent thermal insulation, reducing thermal conductivity by 30-50% compared to brick walls, which helps reduce heating and cooling costs.

Sound absorption and noise reduction:The porous structure of stone wool effectively absorbs sound, reducing noise levels to 30-40 decibels, which is ideal for noisy areas such as factories or highways.

Fire resistance:Stone wool is a non-combustible material with a high melting point, which prevents the spread of flame and delays the destruction of the structure, increasing fire safety in industrial conditions.

Easy and simple installation:These panels are lightweight and easy to install, reducing transportation and construction time, ideal for temporary or emergency construction projects.

Product Introduction

Stone cotton sandwich panels is a highly effective building material designed to ensure excellent thermal insulation, sound absorption and fire resistance. Consisting of a core of stone cotton wool, clamped between two layers of steel, these panels provide excellent heat efficiency, reducing the energy consumption for heating and cooling to 50 %. The porous structure of stone wool also helps to absorb and block the sound, which makes it an ideal solution for rooms with a high noise level, such as factories or buildings near highways. In addition, fire resistant properties with high melting temperature inherent in the stone, increase the safety of buildings, delaying the spread of flame and providing a critically important time for evacuation. Light and simple in installation, sandwich panels made of stone cotton wool are ideal for both permanent and temporary structures, providing rapid installation and reduction of labor costs. Be it residential, industrial or commercial buildings, these panels are an effective solution for energy -efficient, soundproofing and fireproof buildings.

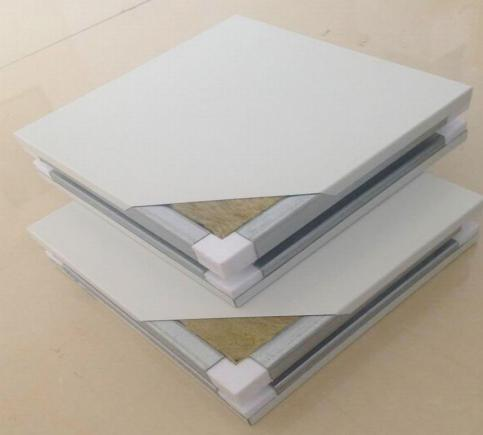

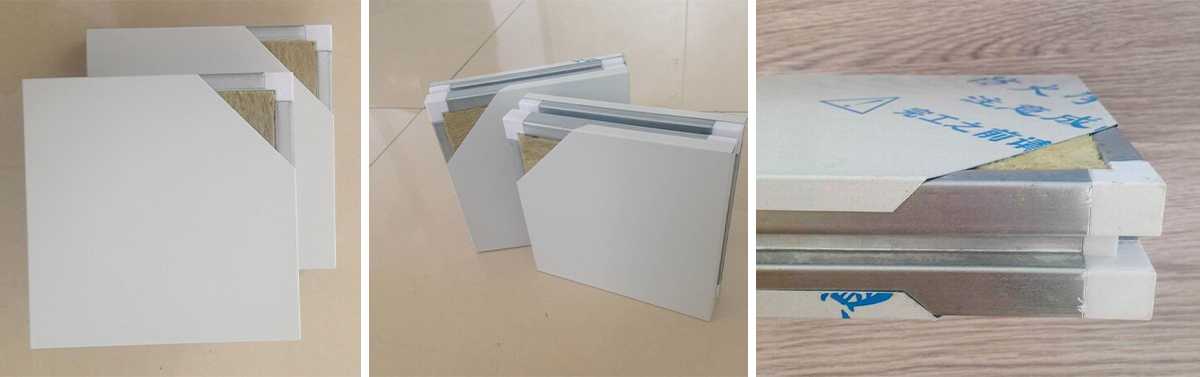

Composition and structure

Sandwich panels with colored steel cotton wool consist mainly of three parts. The outer layers are sheets of colored steel, which are usually made of galvanized steel covered with a layer of color organic coating. This color coating not only gives panels an attractive appearance, but also provides a certain corrosion resistance. For example, common colors are white, blue and gray, which can be selected in accordance with various scenarios and aesthetic requirements.

The main material is stone cotton wool. Stone cotton wool is an inorganic fibrous material obtained by melting basalt and other natural rocks at high temperatures and their subsequent fibrous grinding during a special process. It has good heat -insulating, sound -absorbing and refractory properties. The thickness of the stone cotton wool layer in sandwich panels can vary, as a rule, from 50 to 200 mm, depending on specific needs. For example, in the buildings of refrigerator chambers, to achieve better thermal insulation, you can choose a thicker layer of stone wool.

These three parts are connected together using adhesive or mechanical mounting methods, forming a strong design of a sandwich panel. Thanks to a dense connection, the panel retains its integrity and stably performs its functions in various conditions.

Scenarios are applied

Industrial buildings: In factories, warehouses and workshops, rock wool sandwich panels with colored steel are widely used for roofing and walling. Their good thermal insulation and fire-resistant properties allow them to meet the needs of industrial production, reducing energy consumption and ensuring production safety.

Commercial buildings: In shopping malls, supermarkets and exhibition halls, these panels can be used in some partitions and decorative roof elements. Their attractive appearance and sound-absorbing characteristics help create comfortable conditions for visiting stores and exhibitions.

Residential Buildings: In some rural self-built or small prefabricated houses, rock wool colored steel sandwich panels are also used for external walls and roofs. They can provide warm and quiet living conditions at a relatively low construction cost.

Temporary buildings: For example, offices on construction sites, temporary dormitories and shelters for victims of natural disasters. The lightness and ease of installation of the panels make them the first choice for such temporary buildings.

Maintenance and precautions

Regular inspection: The surface of the sandwich panels should be regularly checked for any signs of damage, such as scratches on the colored steel sheets or weakening of the bond between the layers. If any problems are found, they should be promptly corrected to ensure the normal operation of the panels.

Cleaning: The surface of the panels can be cleaned regularly with mild detergents and soft cloths to remove dust and dirt to maintain their appearance. However, do not use sharp or abrasive tools to avoid damaging the color coating.

Avoid Impact: During operation, try to avoid strong impacts on the panels to avoid deformation or damage to the structure, which may affect their thermal insulation, sound absorption and other functions.

Specifications

Surface materials: color coated steel sheet, galvanized steel sheet, stainless steel sheet, antistatic sheet, inorganic pre-coated sheet, corrosion-resistant sheet, etc.

Inner core material: stone wool.

Structural frame: Cold drawn galvanized sheet or aluminum frame is used for perimeter.

Thickness: 50mm, 75mm, 100mm;

The thickness of color steel sheet is usually 0.426mm-0.6mm;

Width: Generally use 1180mm or 980mm, non-standard panel with any width;

Length: can be made according to requirements (total length ≤ 6000mm)

Element |

Options |

Thickness of steel sheet |

0.376 mm – 0.5 mm |

Main material |

Stone wool |

Sealing steel plate |

Galvanized steel plate 0.5mm – 0.8mm |

Width |

980 mm, 1180 mm |

Thickness |

50mm, 75mm, 100mm, 150mm |

Length |

Custom size |

Surface protection |

Transparent plastic film |

Fire resistance class |

A |

Fire resistance duration |

1 – 4 hours |

Thermal conductivity |

≤0.043 W/m·K |

Density of stone wool |

100 kg/m³ |

Thermal insulation |

Good thermal insulation, effectively prevents heat transfer and maintains a stable indoor temperature. |

Soundproofing |

It has good soundproofing properties and reduces the impact of external noise. |

Dust protection |

Excellent dust protection, smooth and even surface prevents dust accumulation. |

Antibacterial properties |

Antibacterial treatment is possible, the degree of bacterial suppression is more than 99% (Escherichia coli, Staphylococcus aureus, etc.). |

Anti-corrosion properties |

Stainless steel and protective coating are resistant to alcohol and disinfectant solutions, suitable for frequent disinfection. |

Surface evenness |

The panels are manually pressed layer by layer, surface error ≤ 0.5 mm. |

Load capacity |

Fastening is carried out using adhesive bonding and riveting, load capacity up to 150 kg/m². |