Mechanical Sandwich Panel with Foam Filler

Light weight– facilitates transportation and installation

Good thermal insulation– thanks to the cellular structure of EPS

Economical– the optimal solution in terms of price and functionality

Quick installation– thanks to standard dimensions and connection

Wide choice of facings- different colors and textures according to RAL

Resistance to moisture and chemicals– thanks to galvanization

?Brief Product Description

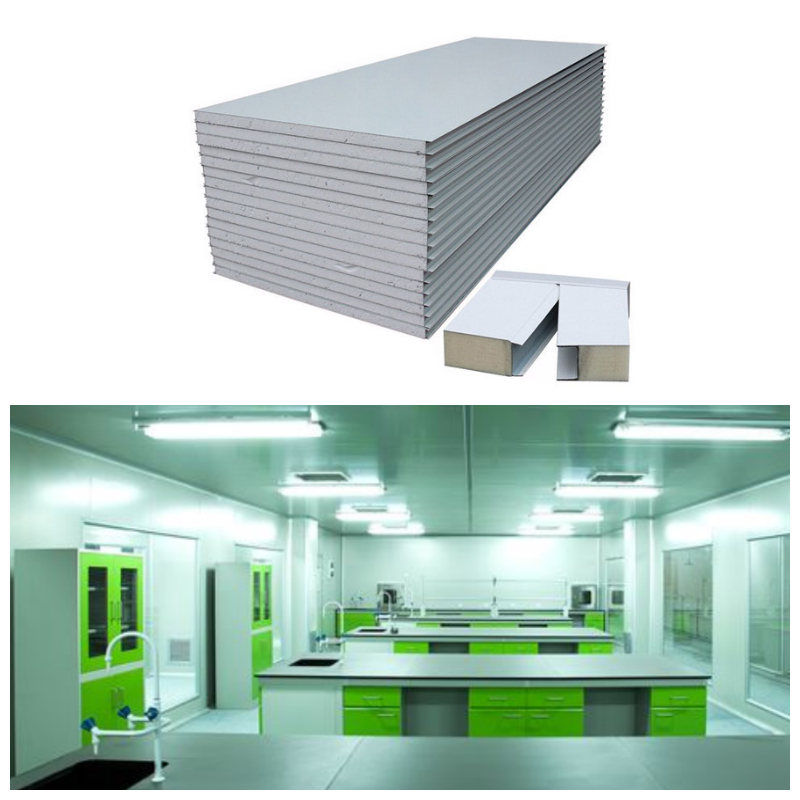

Machined sandwich panels with expanded polystyrene core and colored steel cladding are an economical and lightweight building material widely used in prefabricated buildings, clean rooms, warehouses and manufacturing facilities.

?Product details

Panel type:sandwich panel with polystyrene foam core

Lining:painted galvanized steel (RAL colors to choose from)

Production method:automated production line

Structure:three layers - steel + EPS + steel

Connection form:lock connection (concealed fixation possible)

⚙️Specifications

| Parameter | Meaning |

|---|---|

| Panel thickness | 50/75/100/150 mm |

| EPS Density | 10–18 kg/m³ |

| Thickness of the cladding | 0.376–0.6 mm (on request) |

| Panel width (useful) | 950/1150 mm |

| Panel length | up to 12 m (on request) |

| Thermal conductivity | ≤ 0.038 W/m·K |

| Fire resistance time | 1-3 Hours |

| Color | RAL 9003, RAL 9016, etc. |

✅Product benefits

Light weight– facilitates transportation and installation

Good thermal insulation– thanks to the cellular structure of EPS

Economical– the optimal solution in terms of price and functionality

Quick installation– thanks to standard dimensions and connection

Wide selection of claddings- different colors and textures according to RAL

Resistance to moisture and chemicals- thanks to galvanization

?Applications

?️ Prefabricated buildings and hangars

? Warehouse and production facilities

? Cold storage (not for sub-zero temperatures)

? Clean rooms and modular designs

? Internal partitions, enclosing structures