Magnesite-Mineral Wool Sandwich Panel

?Maximum fire resistance

Ideal for fire barriers and areas with high safety requirements.

?Hygienic surface

The smooth surface prevents the accumulation of dust and germs and is easy to clean and disinfect.

?Soundproofing and thermal insulation

Thanks to the stone wool filling, the panels effectively dampen noise and retain heat.

?️Flexibility and precision

Manual assembly allows for precise adaptation of panels to non-standard shapes, openings and built-in elements.

?Compatibility with clean rooms

The materials comply with sanitary and hygienic standards for laboratories and medical institutions.

?Product description

Hand-made sandwich panel based on glass-magnesium sheet and stone wool is a high-tech construction solution for clean rooms requiring increased fire resistance, sound insulation and hygienic cleanliness.

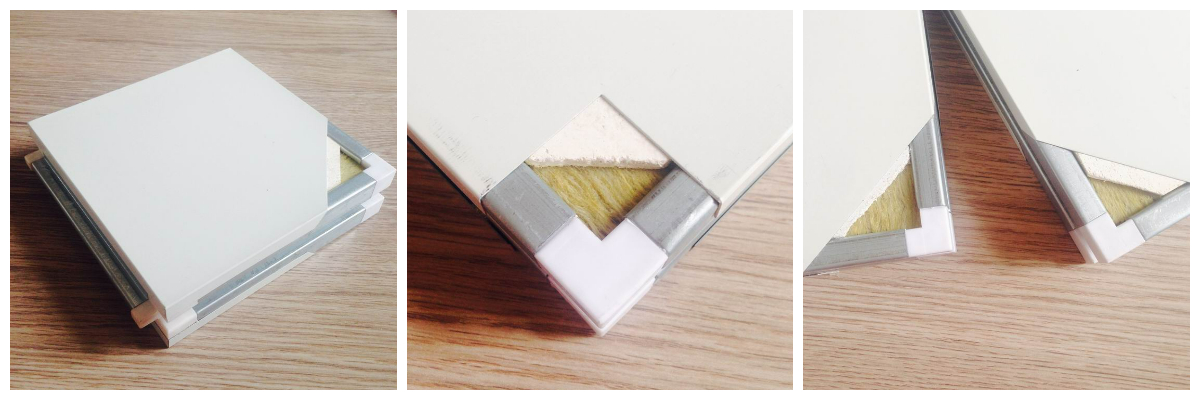

The panel is handcrafted to achieve a precise fit, reliable sealing and increased structural stability. The outer and inner layers are made of painted galvanized steel, the internal structure includes non-flammable glass-magnesium plate and high-density mineral wool.

⚙️Specifications

| Parameter | Meaning |

|---|---|

| Construction | Manual assembly |

| Faceplates | Painted galvanized steel (0.376–0.6 mm) |

| Inner layer | Glass-magnesium sheet + rock wool |

| Density of stone wool | 100–120 kg/m³ |

| Panel thickness | 50/75/100 mm |

| Panel width | 980 mm / 1180 mm |

| Length | Up to 6000 mm (on request) |

| Fire safety time | 1-3 hours |

| Thermal conductivity | ≤ 0.045 W/(m K) |

| Soundproofing | ≥ 30–32 dB |

| Connection type | Straight edge, aluminum frame, Z-joint, etc. |

✅Product benefits

?Maximum fire resistance

Ideal for fire barriers and areas with high safety requirements.?Hygienic surface

The smooth surface prevents the accumulation of dust and germs and is easy to clean and disinfect.?Soundproofing and thermal insulation

Thanks to the stone wool filling, the panels effectively dampen noise and retain heat.?️Flexibility and precision

Manual assembly allows for precise adaptation of panels to non-standard shapes, openings and built-in elements.?Compatibility with clean rooms

The materials comply with sanitary and hygienic standards for laboratories and medical institutions.

?Applications

Operating and sterile areas

Laboratories, pharmaceutical production

Electronic and semiconductor workshops

Medical equipment production

Clean rooms and GMP areas

Research and food enterprises

?Additionally

Perforated panels for ventilation

Antibacterial coating

Protective film

Possibility of combination with other materials (e.g. aluminum honeycomb)