Stainless steel sandwich panels

Superior Hygiene – The smooth stainless steel metal surface is non-porous and easy to sterilize.

High Structural Strength – Precision handcrafted for strong connection and stability.

Thermal and Sound Insulation – Excellent heat and sound control for standard conditions.

Customizable Design – Available in a variety of thicknesses, surface finishes and core materials.

Durability – Corrosion-resistant stainless steel ensures long service life.

Product description

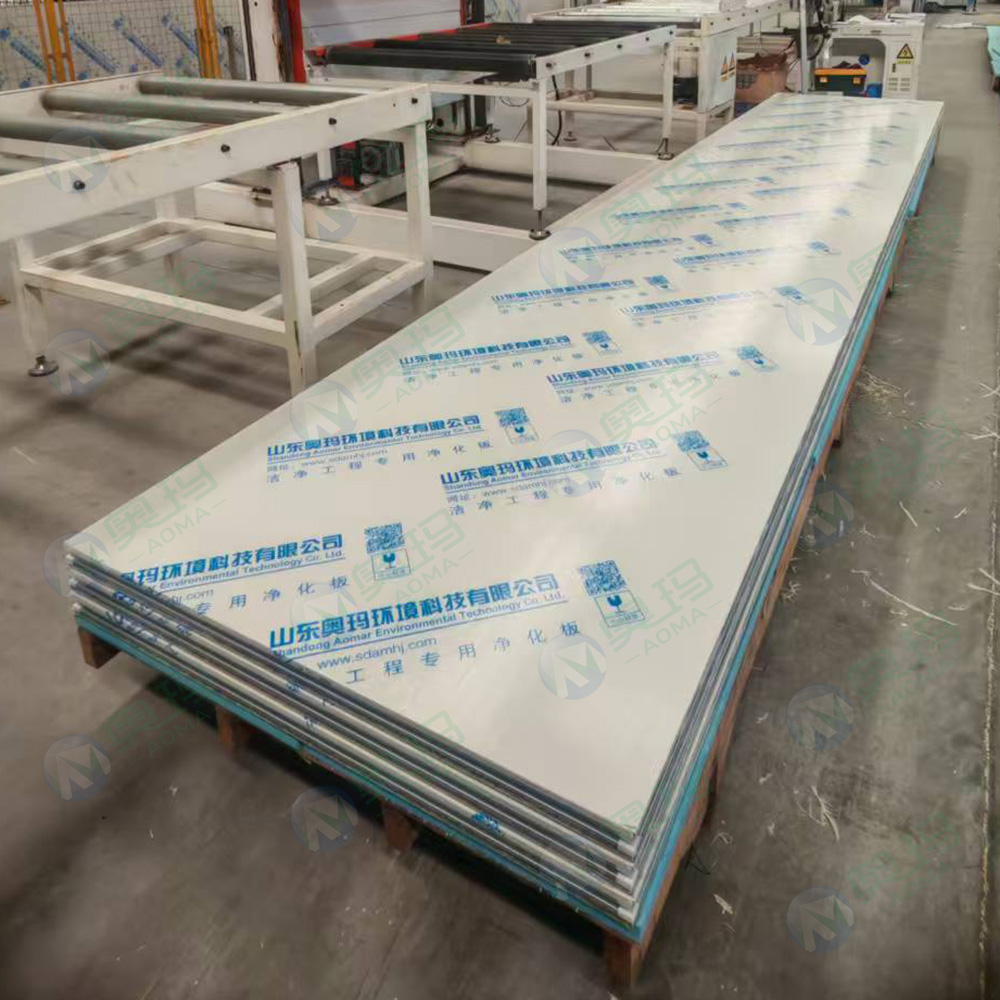

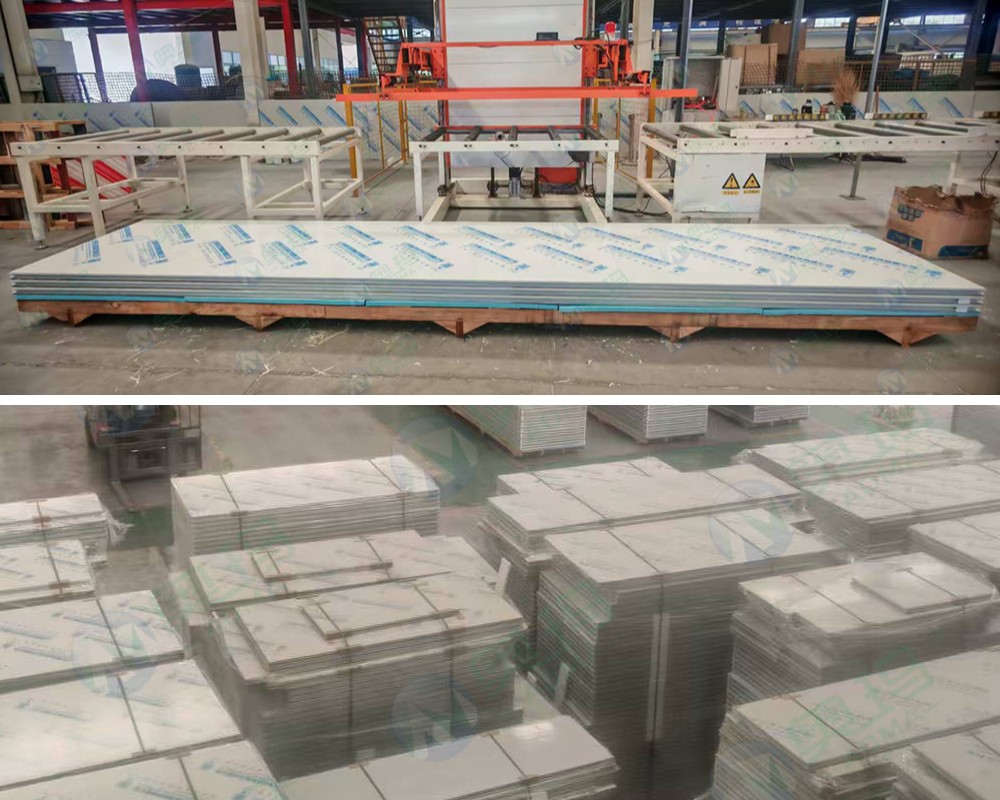

Hand-assembled stainless steel sandwich panels are a high-performance wall and ceiling material designed for cleanrooms, laboratories, hospitals and controlled manufacturing environments. Precision handcrafted, they combine two outer layers of stainless steel with a high quality insulating core, providing maximum structural strength, thermal insulation and disease resistance.

Unlike traditional modular panels, these stainless steel composite panels are manufactured with seamless joints, providing superior sealing and a smooth, easy-to-clean surface. Their reliability and hygienic design make them an ideal choice for GMP cleanrooms, pharmaceutical production lines and facilities with high hygiene requirements.

Technical Parameters

| Characteristics | Details |

| Name of the product | Hand-assembled stainless steel sandwich panels |

| Thickness range | 50mm/75mm/100mm (custom order available) |

| Surface material | 50mm/75mm/100mm (custom order available) |

| Infill material options | Rock wool, polyurethane foam, polystyrene foam, aluminum honeycomb core |

| Panel width | Standard 1180 mm (custom order possible) |

| Length | Up to 6000 mm |

| Surface finishing | Satin / Mirror / Matte |

| Fire resistance | Up to class A (depending on core material) |

| Thermal conductivity | ≤ 0.035 W/(m K) |

| Connection type | Tongue and groove with hidden fasteners |

Key Benefits

Superior Hygiene – The smooth stainless steel metal surface is non-porous and easy to sterilize.

High Structural Strength – Precision handcrafted for strong connection and stability.

Thermal and Sound Insulation – Excellent heat and sound control for standard conditions.

Customizable Design – Available in a variety of thicknesses, surface finishes and core materials.

Durability – Corrosion-resistant stainless steel ensures long service life.

Design and components

Outer layers – high-quality stainless steel sheets SUS 304 / SUS 316L.

Thermal insulation core – rock wool, polyurethane foam, polystyrene foam or aluminum honeycomb structure for special performance requirements.

Sealing Edge – Prevents moisture penetration and ensures a tight fit.

Connecting profile – Hidden fastening system for seamless installation.

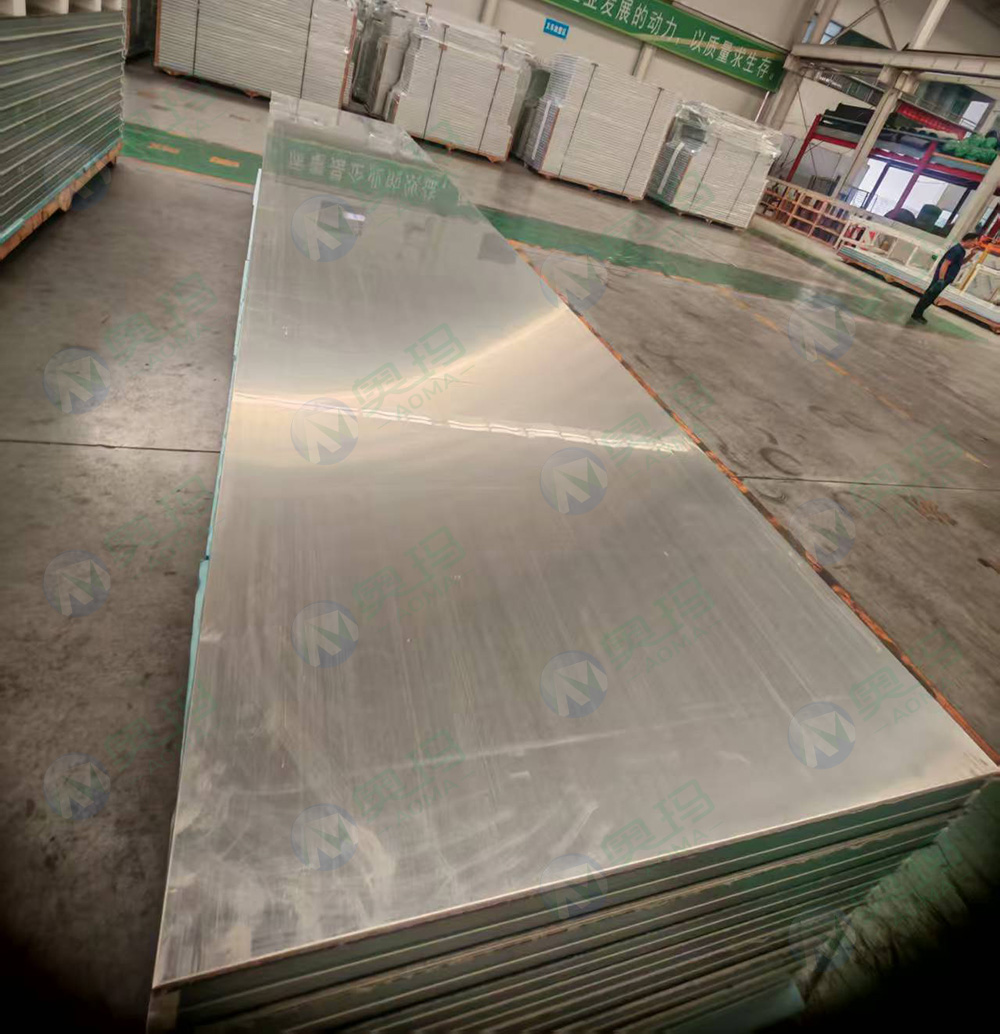

Protective film – Prevents scratches during transportation and installation.

Areas of application

Pharmaceutical Cleanrooms – Sterile production that meets GMP standards.

Hospital operating rooms – Antibacterial and easy-to-clean partitions and ceilings.

Electronic Manufacturing – Dust-free environment for precision assembly.

Food Production – Hygienic surfaces for contamination-sensitive production.

Cold Storage - Excellent insulation for temperature control.

Recommendations for maintenance and care

Surface Cleaning – Use mild detergents and non-abrasive materials to avoid scratching the stainless steel.

Checking Connections – Periodically check the connection seals for leaks.

Core Protection – Avoid drilling or cutting that may damage the insulated core.

Avoid harsh chemicals – Do not use chlorine-based cleaners, which can corrode stainless steel.

Removing the protective film - Remove the film immediately after installation to avoid leaving adhesive residue.