Construction Materials Market: Comparison of Rockwool and PUF Panels Opens New Prospects for the Industry

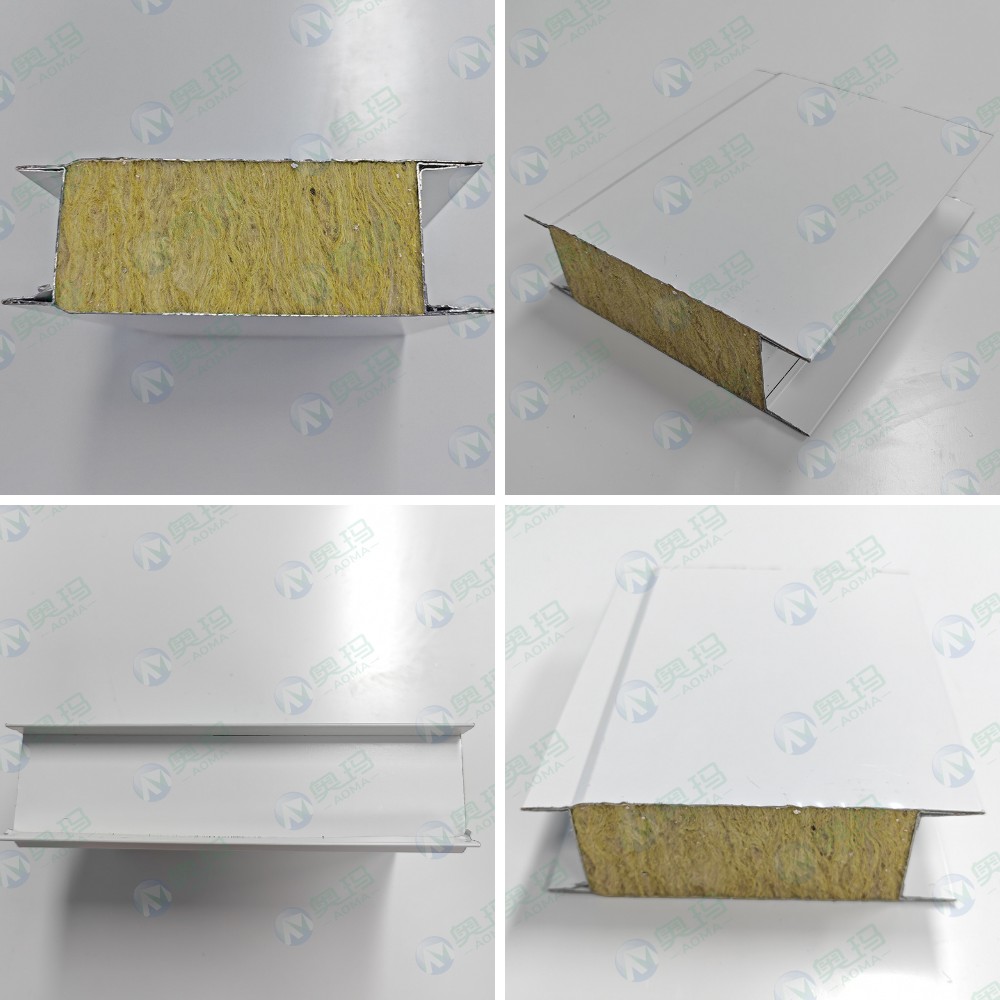

In the modern construction market, special attention is paid to materials that provide high energy efficiency, fire safety and ease of installation. Among the most popular solutions today aresandwich panelswith different types of fillers. The most popular remain panels based on mineral wool (Rockwool) and panels made of polyurethane foam (PUF, orPPU panels).

Rockwool's resistance to extreme temperatures

The mineral wool used as insulation in Rockwool panels is a benchmark for fire safety. These panels can withstand temperatures up to 1000 °C without losing shape or melting. Thanks to this propertymineral woolIt is widely used in objects with increased fire resistance requirements: industrial buildings, warehouses, medical institutions and clean rooms. In addition, Rockwool has excellent sound insulation and durability, which makes such panels in demand in residential and commercial construction.

The ease and ease of installation of PPU panels

Unlike Rockwool,PPU panelsThey differ in relatively low density - about 40–45 kg/m³. This makes them easy, convenient to transport and installation. It is especially important that panels based on polyurethane foam provide a faster installation of clean rooms and refrigeration chambers. Due to its thermal insulation properties, PUF panels reduce energy costs and retain a stable microclimate, which makes them the best choice for warehouse complexes and logistics centers.

Comparative analysis

If we talk about strength and fire safety, Rockwool certainly leads, since mineral wool remains reliable protection even when exposed to open fire. However, PPU panels win in the efficiency and speed of projects, where the rapid construction of wall and roofing structures is required. Thus, the choice between these two types depends on the specific requirements of the customer: fire resistance or ease of installation.

Market prospects

According to analysts, in 2025 the demand forSandwich panelwill continue to grow. In Europe and the CIS countries, the requirements for energy efficiency and fire safety of buildings are strengthened. This will lead to the expansion of the use of both Rockwool and PUF solutions. In medical and pharmaceutical facilities, including operating blocks and laboratories, panels fromMineral wool. At the same time, logistics centers and warehouses, where the speed of construction and a low mass of structures are important, will preferPPU panels.

Conclusion

A comparison of Rockwool and PUF panels shows that both types of materials occupy an important place in the construction industry. Some provide maximum fire protection, others – ease and speed of installation. In the future, construction companies will increasingly combine different technologies, achieving the optimal balance between safety, reliability and cost-effectiveness.