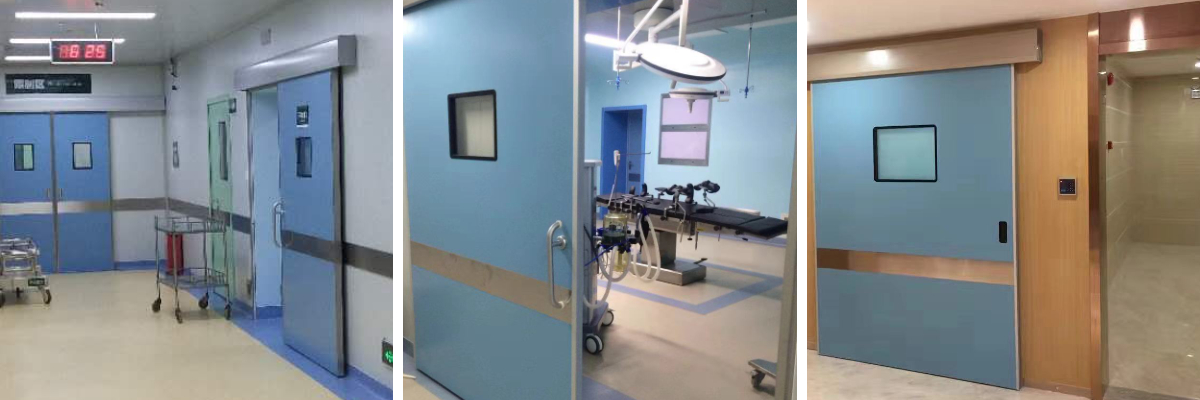

Sealed Automatic Doors for Medical Facilities

Smooth and silent operation

Excellent sealing

Automatic control

Improved Security Features

Ergonomic design

Product description

Cleanroom doors are designed to meet the highest performance and safety standards, combining smooth operation, quiet operation, and outstanding sealing. These doors are essential for maintaining consistent air quality and pressure in clean areas, making them ideal for industries such as medicine, pharmaceuticals, and electronics.

The ergonomic design ensures ease of use for medical staff and safe, unimpeded movement of patients and carts.

Features such as fully automatic operation enhance convenience while minimizing contamination risks, making these doors particularly valuable in environments requiring strict hygiene controls, such as aseptic filling areas and electronics industry assembly lines. With built-in safety mechanisms such as anti-jam sensors and emergency stop buttons, these doors provide maximum protection for personnel and equipment.

Silent operation further supports sensitive processes such as biomedical research and gene sequencing, providing a focused and uninterrupted work environment.

These cleanroom doors are an essential component of modern cleanrooms, ensuring efficiency, safety and compliance with stringent environmental standards.

In the field of modern medical institutions, doors for clean rooms, especially medical hermetic automatic ones, are of particular importance. We present their detailed review.

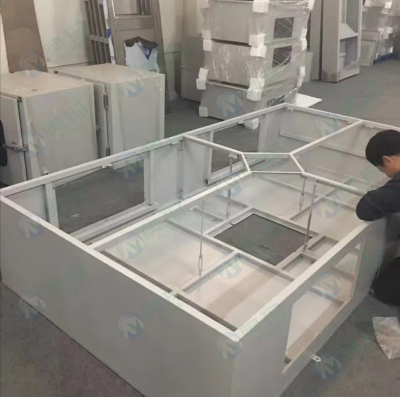

Composition and structure

Door panel: Typically made from high quality materials such as stainless steel or aluminum alloy, which have excellent corrosion resistance. The surface is not only smooth, but also easy to clean, which is essential for meeting strict cleanroom hygiene standards. For example, in a pharmaceutical clean room, the thickness of the door leaf can be from 30 to 50 millimeters. The design provides minimal clearances to improve tightness. The material is often carefully selected to ensure that no particles are released that could contaminate the clean environment.

Drive system: Consists of motor, gearbox and transmission mechanism. The motor serves as a power source, providing automatic opening and closing of the door. The gearbox plays a key role in adjusting speed and torque to ensure smooth operation. High quality cleanroom doors are usually equipped with advanced motors such as servo motors. These motors provide precise control of door movement, ensuring smooth and stable opening and closing. For example, in a semiconductor manufacturing cleanroom, the drive system must operate with extreme precision to prevent any vibrations that could dislodge tiny particles.

Sealing system: This is a key element to ensure the airtightness of cleanroom doors. Special rubber seals are installed around the perimeter of the door frame and leaf. These seals are made of materials with high elasticity and durability. They effectively block the penetration of air, dust and even microscopic contaminants. In a biological cleanroom used for sensitive cell culture research, the containment system plays a vital role in maintaining the required sterility, preventing the entry of external bacteria or other unwanted substances. Includes control panel, sensors and controller. The sensors, which can be infrared or microwave, are highly sensitive.

Infrared sensors can detect thermal radiation from an approaching person, while microwave sensors can detect the movement of objects within a certain radius. The controller processes the signals from these sensors and coordinates the operation of the drive system to ensure timely opening and closing of the door. In a precision medical device manufacturing cleanroom, the control system must operate flawlessly to prevent any unwanted openings that could potentially introduce contaminants.

Areas of application

Clean Rooms for Pharmaceutical Manufacturing: In these areas where drugs are manufactured, clean room doors are used to separate the different stages of production. For example, between the raw material preparation area and the tablet compression area, a door ensures there is no cross-contamination and maintains air quality at the required level.

Cleanrooms for Medical Device Manufacturing: From component assembly areas to final packaging areas, cleanroom doors play a key role in maintaining the cleanliness and accuracy of the manufacturing process.

For example, when assembling pacemakers, even the smallest particles can affect the operation of the device, and a cleanroom door helps prevent such contaminants from entering.

Cleanrooms for biomedical research: Whether culturing stem cells or conducting genetic experiments, cleanroom doors are crucial for creating a controlled and sterile environment. They separate the experimental area from the reagent and sample storage area, ensuring the integrity of the research.

Maintenance and precautions

Regular cleaning: The door surface should be cleaned regularly using approved cleanroom disinfectants. Seals also need to be checked and cleaned regularly to maintain optimal sealing. In a vaccine production cleanroom, any contamination on the door or seals can compromise the sterile environment.

Component Inspection: Qualified service personnel should periodically inspect the drive system, sensors, and other components. Any signs of wear or malfunction must be repaired immediately. In a high-tech cleanroom for the production of advanced medical diagnostic equipment, a faulty door can disrupt the entire production process.

Correct Operation: Users should not forcefully push or pull the door when it is operating in automatic mode.

In addition, established entry and exit procedures should be followed to avoid unnecessary openings that could compromise the integrity of the cleanroom. In conclusion, cleanroom doors, especially medical sealed automatic ones, are indispensable for creating and maintaining strictly controlled and hygienic conditions required in various medical and allied industries. Their proper operation and maintenance are critical to the successful execution of many mission-critical processes.

Technical Parameters

| Position | Options |

| Door width | 1070mm~1570mm |

| Structure width | 2350mm~3350mm |

| Door opening speed | 250~500 mm/s (adjustable) |

| Door closing speed | 250~500 mm/s (adjustable) |

| Opening time | 2–20 s (adjustable) |

| Clamping force | F>70 N |

| Manual drive force | F<100 Н |

| Power consumption | ≤150Вт |