Transfer chamber

Pollution Prevention: The main advantage of transfer chambers is their ability to prevent pollution.

By acting as a buffer zone, they minimize the direct transfer of dust, particles and microorganisms between different areas.

Improved tightness: The doors of the transfer chambers are equipped with high-quality sealing mechanisms, and the locking system ensures that only one door is open at a time.

Convenient Material Handling: Transfer chambers provide a convenient way to move materials, equipment and even personnel between different areas.

Space saving:Compared to other methods of separating and connecting different zones, transfer chambers are relatively compact.They can be installed in confined spaces, providing an efficient solution for spaces where every square meter counts.

A pass-through chamber is an essential piece of equipment in cleanrooms and other controlled access areas. It serves as a transition space, allowing materials, equipment, and sometimes personnel to move between different areas, minimizing the possibility of contamination or the spread of unwanted substances.

Detailed Description:

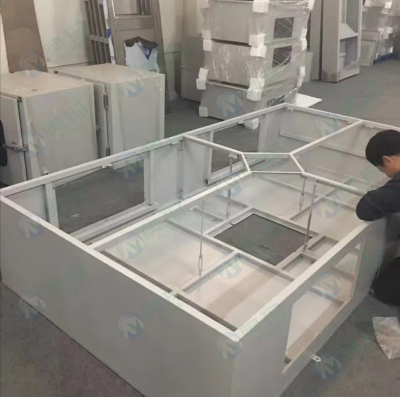

Design and components

Camera body:

Typically made of stainless steel or other corrosion-resistant and easy-to-clean materials, the housing provides a sealed environment. It has smooth interior surfaces to prevent the accumulation of dust, dirt, and microorganisms, facilitating effective cleaning and disinfection.

Doors: The passage chamber has at least two doors on opposite sides. These doors typically feature advanced sealing mechanisms to ensure airtightness when closed. They can be manual or automatic and are designed to open and close smoothly to prevent dust formation and minimize disruption to air pressure and cleanliness in surrounding areas.

Locking system: A locking device is installed to ensure that only one door can be opened at a time. This prevents direct air exchange and the passage of contaminants between two connected areas, maintaining the integrity of the clean or controlled space.

Internal equipment: Some walk-through chambers are equipped with shelves, trays or other elements for convenient placement and transfer of items. These elements are also made from cleanroom-compatible materials and are designed for easy removal for cleaning.

Operating principle

The passage chamber operates on the principle of creating a buffer zone.

When an item needs to be transferred from one area to another, it is placed into the cell through one door.

After the first door is closed and sealed, the chamber can be subjected to various treatments, such as air purification, ultraviolet (UV) disinfection, or chemical sterilization, depending on the specific requirements of the process.

Once processing is complete, another door opens, allowing the item to be retrieved into the adjacent area.

This process helps prevent contaminants from the outside environment or from an area with a lower level of cleanliness from directly entering a cleaner area.

Application

Pharmaceutical industry:

In pharmaceutical manufacturing facilities, walk-through chambers are widely used to transfer raw materials, packaging materials, and finished products between different cleanrooms, such as from the preparation area to the packaging area.

They help maintain product sterility and quality by preventing contamination during transmission.

Biotechnology and research laboratories:

In these environments, walk-through chambers are used to transfer samples, reagents and laboratory equipment between different areas with different levels of cleanliness and isolation.

For example, when working with infectious agents or highly sensitive biological samples, a pass-through chamber provides a safe and controlled way to move materials without the risk of cross-contamination.

Electronic production:

In the production of semiconductors and other electronic components, flow cells are used to transfer wafers, masks, and other fragile components between different production areas.

Since these components are highly sensitive to dust and particles, a pass-through chamber helps maintain the required cleanroom conditions and prevent defects caused by contamination.

Food industry:

In some food production facilities with high hygiene requirements, such as those producing ready meals or baby food, pass-through chambers are used to transfer food ingredients and packaging materials between different production areas.

This helps prevent the ingress of foreign particles and microorganisms, ensuring the safety and quality of food products.