Price of sandwich panels with paper honeycomb

Easy

High strength to weight ratio

Good shock-absorbing properties

Definition and structure

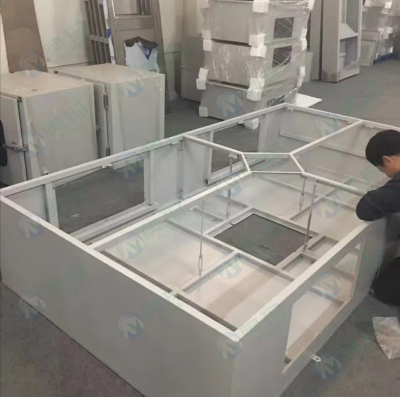

Machine-made paper honeycomb sandwich panel is a composite material consisting of a paper honeycomb core and two outer layers.

Honeycomb core is made from special paper by folding, gluing and curing to form a hexagonal honeycomb structure. This structure has excellent mechanical properties and provides good support and shock absorption. The outer layers are usually made of various materials such as paper, cardboard, plastic or metal, which are bonded to both sides of the honeycomb core to form the finished composite panel.

Characteristics

Lightweight: Due to its unique honeycomb structure, the paper honeycomb composite panel has a relatively low density, making it significantly lighter than traditional solid panels of the same size and thickness. This lightness simplifies handling, transport and installation, reducing labor and transport costs.

High strength to weight ratio: Although lightweight, the paper honeycomb composite panel is relatively strong. The honeycomb core effectively distributes the load, providing the panel with good resistance to compression, tension and bending. It can withstand certain pressures and impacts without slight deformation or damage, meeting the requirements of many applications.

Good shock-absorbing properties: The honeycomb structure has excellent shock-absorbing properties and can effectively absorb and dissipate impact energy. When exposed to external forces, the honeycomb core can be deformed to a certain extent, softening the impact, thereby performing a protective function for objects placed on the panel or products packaged using it.

Sound and heat insulation: The paper honeycomb composite panel also has certain sound insulation and heat insulation properties. The air-filled honeycomb structure can block the transmission of sound and heat to a certain extent, helping to reduce noise levels and maintain indoor temperature stability. This gives it some application value in the areas of building finishing and packaging where sound and thermal insulation is required.

Eco-friendly: Paper is a renewable and degradable material, so the paper honeycomb composite panel has good environmental performance. It is recyclable and can reduce environmental pollution compared to some non-degradable composite materials. In addition, the production process of paper honeycomb composite panel requires relatively less energy and resources, which is in line with sustainable development trends.

Application

Packaging industry:It is widely used for packaging various products such as electronic devices, precision instruments, glass products, etc. Its lightness, high strength and good shock-absorbing properties effectively protect packaged goods during transportation and storage, reducing the risk of damage.At the same time, the environmental performance of paper honeycomb composite panel meets the requirements of green packaging.

Building decoration: In the field of building finishing, paper honeycomb composite panel can be used as partition walls, ceiling panels, wall panels, etc. Its light weight facilitates installation and installation, and also provides sound and heat insulation, increasing the comfort of the building's internal environment. In addition, the surface of the composite panel can be processed in a variety of colors and textures to meet different decorative needs.

Furniture Making: It can be used to make furniture such as countertops, cabinet doors and drawers. The lightness and high strength of a composite panel with paper honeycomb can reduce the weight of furniture while maintaining its structural strength, and also save wood resources, which contributes to the sustainable development of the furniture industry.

Automotive and Aerospace: In some special cases, paper honeycomb composite panel is also used in Automotive and Aerospace industries. For example, it can be used in certain interior trim components of automobiles and aircraft, using its lightweight and high strength advantages to reduce vehicle or aircraft weight, improve fuel efficiency or flight performance, and meet certain sound and thermal insulation requirements.