Laminar Ceiling For Operating Rooms

Laminar air flow:Provides a unidirectional, smooth air flow to remove contaminants and maintain high air purity, which is essential for areas such as operating rooms.

Highly efficient air filtration:The combination of pre-filters and HEPA filters ensures compliance with the most stringent air quality standards required for pharmaceutical and sterile manufacturing.

Uniform air distribution:Provides uniform air flow across the entire area, preventing hot spots and maintaining stable conditions in clean rooms.

Noise reduction:Operates with minimal noise thanks to an improved fan design and sound-insulating materials,

Introduction of the product

A ceiling with a laminar air flow is an advanced solution to maintain high air purity in critical environments. Its unidirectional air flow provides even, parallel air flows, usually moving from the ceiling down. This design effectively removes pollution, which makes it indispensable in rooms such as operating rooms, where it helps to reduce the level of infection of surgical sections by supplying clean air and removing particles and bacteria transferred through the air.

Equipped with a combination of preliminary cleaning filters and HEPA filters, the system ensures that the quality of the air meets the highest standards. This is especially important for clean premises of pharmaceutical production, where a medium free from particles is required for sterile manufacturing of medical products.

The system of diffusers and perforation of the ceiling panels provide uniform air distribution, maintaining the constant quality and temperature of the air throughout the area. Such an uniform distribution is especially useful for large clean rooms, for example, for the production of electronics, where a constant air flow prevents hot spots and ensures that all jobs receive clean air.

Despite its powerful performance, the system works with a minimum noise level. The improved fan design and soundproofing materials make it ideal for quiet rooms, such as research laboratories or hospital wards.

Due to the excellent air purity, efficiency and silent work, the ceiling of laminar air flow is the most important component for maintaining the purity of the environment in various industries.

Composition and structure

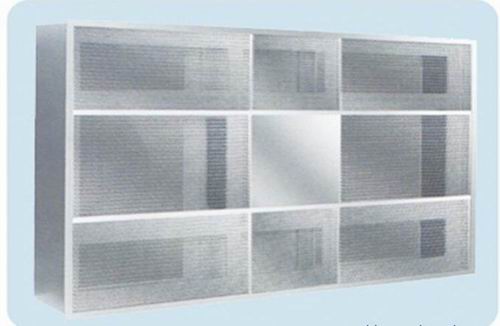

Panel structure: ceilings with a laminar air flow usually consist of several panels. These panels are usually made of high -quality materials such as stainless steel or aluminum alloy, which are resistant to corrosion and are easily washed. The surface of the panels is smooth to prevent the accumulation of dust and other contaminants. Each panel contains a network of small holes or perforations through which air is distributed. For example, in the operating hospital, the smooth surface of the ceiling panels with a laminar air flow allows disinfection, and perforation provides uniform distribution of clean air.

The air processing unit: the heart of the ceiling system of laminar air flow is a ventilation installation. It consists of blower or fans, filters and air ducts. The blower provides the necessary power of air movement. Filters play an important role in air purification. Usually there are preliminary filters and highly effective filters of solid particles (HEPA). Preliminary filters capture larger particles, such as dust and pile, while HEPA filters can remove particles a size of 0.3 micron with an efficiency of up to 99.97%. In the clean room for the production of semiconductors, the HEPA filters in the ventilation installation provide the highest purity of air supplied to the ceiling with laminar air flow. The air duct system evenly distributes the filtered air through the ceiling panels.

The diffuser system: the diffuser system is designed for uniform distribution of filtered air in the form of laminar flow. It is built into the ceiling panels and consists of snot or cracks that direct the air down parallel and smoothly. In laboratory conditions, such a laminar air flow helps to prevent mixing of contaminated air with clean, creating a stable and clean working environment. The angle and size of the diffusers can be adjusted to optimize the distribution of air in accordance with the specific requirements of the room.

Application scenarios

Hospital Operating Rooms: In operating rooms, laminar air flow ceilings are used to create a sterile environment. Laminar air flow helps to keep airborne contaminants out of the surgical area, reducing the risk of post-operative infections. Clean air also benefits the surgical team, providing a comfortable and healthy work environment.

Pharmaceutical and Biotech Labs: These ceilings are essential for maintaining sterile and clean air in labs where drugs are developed, cell cultures are grown, and sensitive biological experiments are conducted. Laminar air flow prevents the entry of external contaminants and helps maintain the integrity of experimental processes.

Pure rooms for the production of semiconductors and electronics: in the production of high -precision electronics, such as microchips, a clean and worthless environment is very important. The ceilings with a laminar air flow provide the necessary cleaning and distribution of air to protect the production process from pollution with solid particles, guaranteeing the quality and productivity of the final product.

Maintenance and precautions

Regular filter replacement: filters in the ventilation installation must be replaced regularly. Pre -cleaning filters can require replacement more often than the HEPA filters, depending on the level of dust and other solid particles in the air. In loaded operating hospitals or industrial clean rooms, the filter replacement schedule should be strictly adhere to to ensure constant highly effective air filtration.

Cleaning ceiling panels: ceiling panels should be regularly cleaned using appropriate disinfectants and cleaning methods. For example, in pharmaceutical clean rooms, a special cleaning protocol can be developed to ensure that there are no residues on the panels that can affect the quality of the air. Perforations and diffusers must also be checked and cleaned to maintain the correct distribution of air.

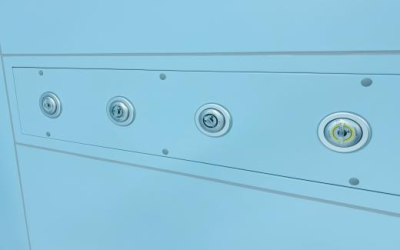

System monitoring: it is necessary to regularly monitor the operation of the ventilation installation, including the fan speed, air flow and air pressure. Any abnormal indicators can indicate a problem in the system, for example, clogging the filter or fan malfunction. In such critical conditions as an operating or high -tech clean room, an immediate response to such problems is necessary to maintain the integrity of the clean environment.

Technical parameters

Model |

I |

Ⅱ |

Ⅲ |

The effectiveness of filtering |

99.999% |

99.999% |

99.99% |

Air flow speed (m/s) |

0.45 |

0.3 |

0.23 |

Air outlet surface size (mm) |

2600×2400 |

2600×1800 |

2600×1400 |

Overall dimensions (mm) |

2680×2480×500 |

2680×1880×500 |

2680×1480×500 |

Air duct dimensions (mm) |

Individual order |

Individual order |

Individual order |

Application scenarios |

Operating room with special cleanliness (class I) |

Standard Clean Operating Room (Class II) |

General clean operating room (class III) |