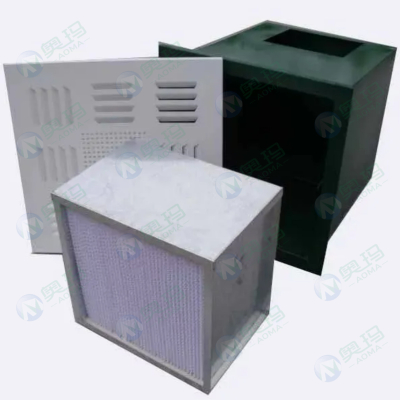

Suspended Electrolytic Steel Plate

Excellent hygiene

Excellent corrosion resistance

High mechanical strength

Electromagnetic compatibility

Custom sizes and colors are available

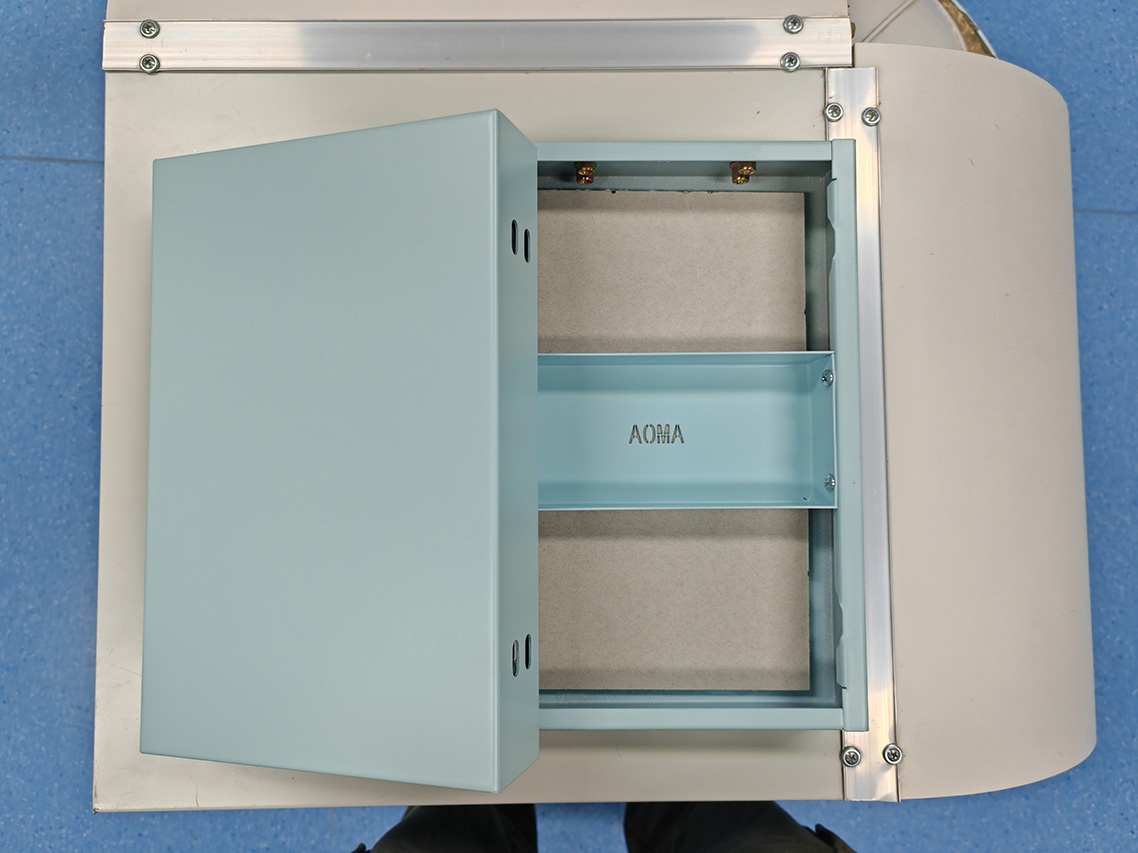

Electrolytic steel plate for operating rooms

Introduction

In demanding operating room environments where strict hygiene, corrosion resistance and electromagnetic compatibility are critical, electrolytic steel plates have become the construction material of choice. These plates are designed to meet the special requirements of such sensitive medical areas, ensuring the safety and success of surgical procedures.

Characteristics of the material

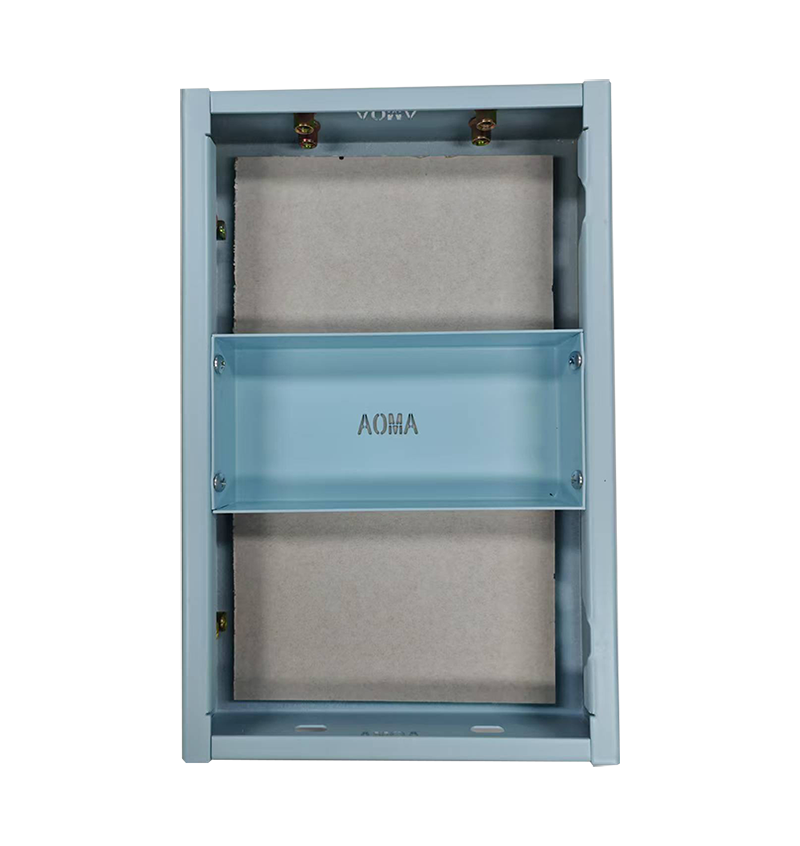

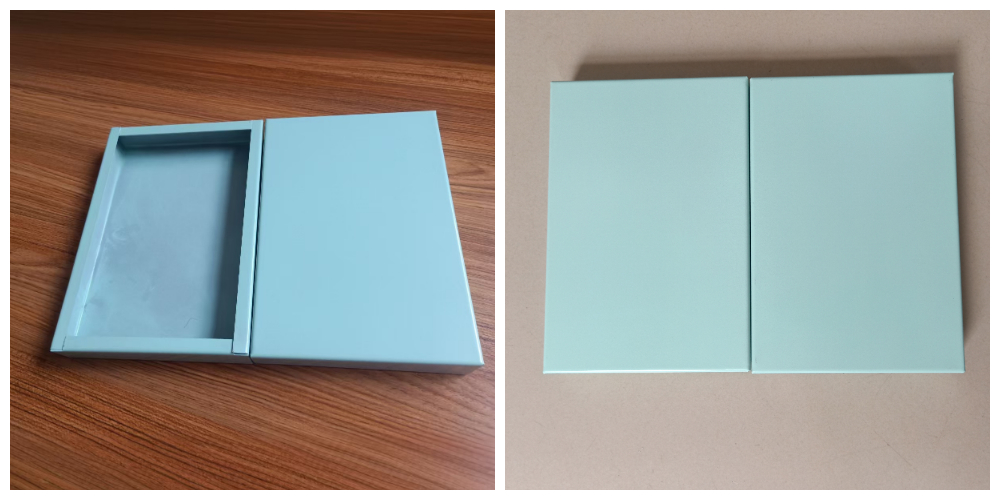

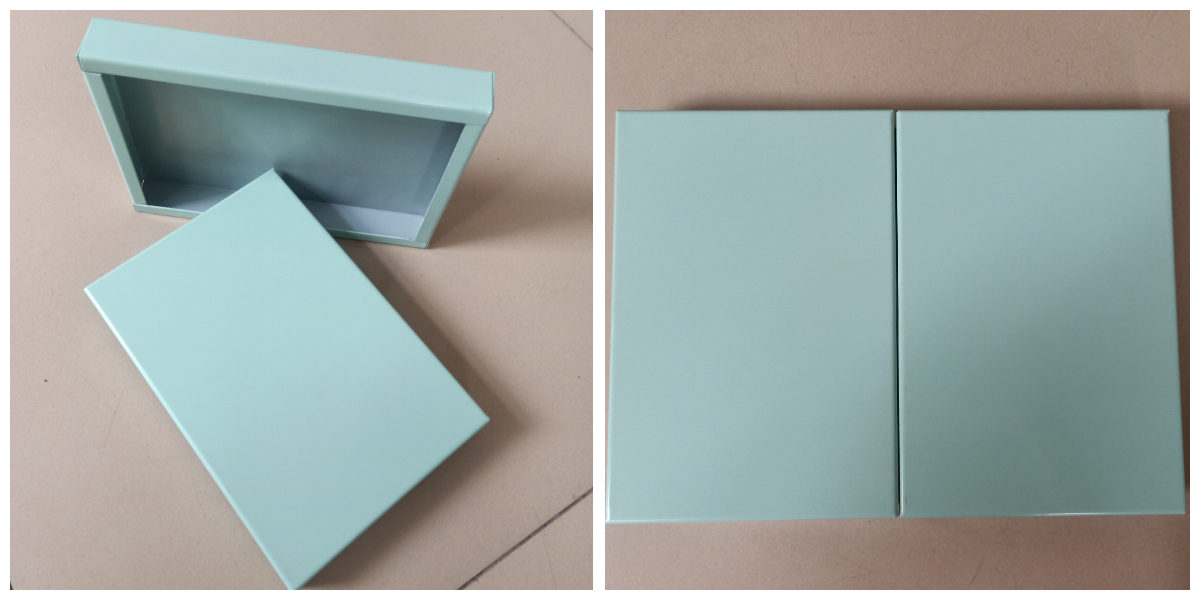

Surface quality

Smooth finish: electrolytic steel slabs used in operating rooms have an exceptionally smooth surface. The electrolytic process removes impurities and creates an uniform, mirror coating. This smoothness is extremely important, as it prevents the accumulation of dust, bacteria and other pollution. In the operating room, even the smallest particle can cause an infection, so the smooth surface of the steel slab provides easy cleaning and disinfection, maintaining the sterile environment.

Antiadgesic properties: the surface of an electrolytic steel slab has natural anti -adhesive characteristics. It is difficult for bacteria and other microorganisms to attach to the surface, which reduces the risk of biofilm formation. This property is extremely important for the long -term maintenance of hygiene in the operating room, since biofilles can be a source of stable infections.

Corrosion resistance

Electrolytic coating:

Steel plates are coated with a thin layer of metal by electrolysis, usually zinc or a zinc alloy. This coating acts as a protective barrier to prevent corrosion of the underlying steel. In the operating room, where the environment may be exposed to moisture (due to surgical procedures, cleaning agents, etc.) and various chemical disinfectants, corrosion resistance is of paramount importance. The electrolytic coating ensures that the steel plate remains intact and functional for a long time, without the risk of corrosion or deterioration that would compromise the structural integrity of the operating room.

Mechanical strength

High Tensile Strength: Electrolytic steel plates have high tensile strength, allowing them to withstand the mechanical stress associated with installation and operation in the operating room. They are capable of supporting the weight of equipment, withstanding shock from accidental collisions, and maintaining their structural integrity under normal wear and tear in a high-intensity surgical environment. This strength is critical to the safety of the operating room and its occupants.

Installation and integration

Installation process

Precise Installation: Installation of electrolytic steel plates in the operating room requires high precision. The plates are carefully measured and cut to fit the specific dimensions of the room. They are then installed using specialized fastening systems to ensure a secure, tight fit. The joints between the plates are carefully sealed to eliminate any gaps through which contaminants could penetrate. This precision installation process is performed by trained technicians to ensure the integrity of the hygienic operating room environment is maintained.

Integration with other systems

Electromagnetic compatibility: in modern operating rooms a wide range of electronic and medical equipment is used. Electrolytic steel plasters are developed taking into account electromagnetic compatibility. They do not interfere with the operation of sensitive medical equipment, such as MRI devices, X -ray installations and electrocardiogram monitors (ECG). Such compatibility is extremely important for accurate diagnosis and treatment during surgical procedures, since any electromagnetic interference can lead to incorrect indications or malfunctions in the operation of equipment. Integration with ventilation and lighting systems:

Steel plates are integrated with the ventilation and lighting systems of the operating room.

The smooth surface of the plates ensures easy installation of ventilation ducts and lighting fixtures. The plates can also be designed to effectively reflect light, improving overall lighting in the operating room while maintaining a glare-free environment, which is critical for surgeons performing delicate procedures.

Service and hygiene

Cleaning

Easy to Clean Surface: As mentioned earlier, the smooth surface of the electrolytic steel plate makes the cleaning process easy. Regular cleaning using mild detergents and disinfectants is sufficient to remove dirt, blood and other contaminants. The anti-adhesive properties of the surface also mean that less effort is required when cleaning, reducing the risk of surface damage and ensuring the longevity of the plate.

Disinfection

Chemical resistance: electrolytic steel plate is highly resistant to a wide range of chemical disinfectants usually used in operating rooms. This ensures effective disinfection of the premises between surgical procedures, destroying the remaining bacteria, viruses or fungi. The chemical resistance of the plate guarantees that multiple disinfection cycles do not cause corrosion or destruction of the material, preserving high standards of operating room hygiene.

Application in operating room design

Bath and ceilings design

Hygienic barrier: Electrolytic steel plates are commonly used for the construction of operating room walls and ceilings. They serve as a hygienic barrier, preventing the penetration of contaminants from outside the room. The smooth, seamless surface of the plates also gives the operating room a clean, modern look that is not only aesthetically pleasing, but also psychologically comfortable for patients and medical staff.