Electrolytic Steel Panel For Operating Room

Excellent hygiene:The smooth surface is easy to clean and disinfect, preventing the accumulation of dust, bacteria and other contaminants.

Excellent corrosion resistance:An electroplated coating, usually zinc or zinc alloy, acts as a sacrificial barrier, protecting the steel from corrosion caused by moisture and chemical disinfectants in the operating room environment.

High mechanical strength:With high tensile strength, it can withstand the weight of equipment and impact from accidental collisions while maintaining the structural integrity of the operating room.

Electromagnetic compatibility:It does not interfere with sensitive medical equipment such as MRI machines, X-ray equipment and ECG monitors, ensuring accurate diagnosis and treatment.

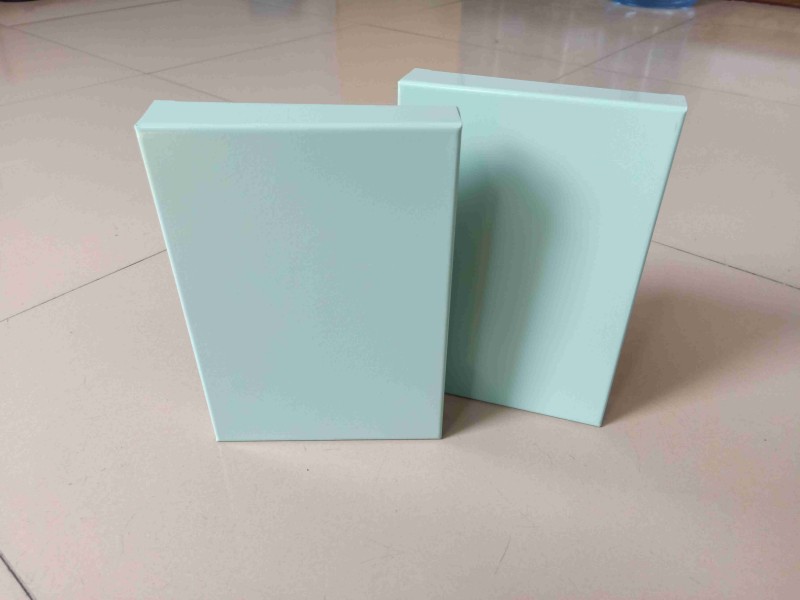

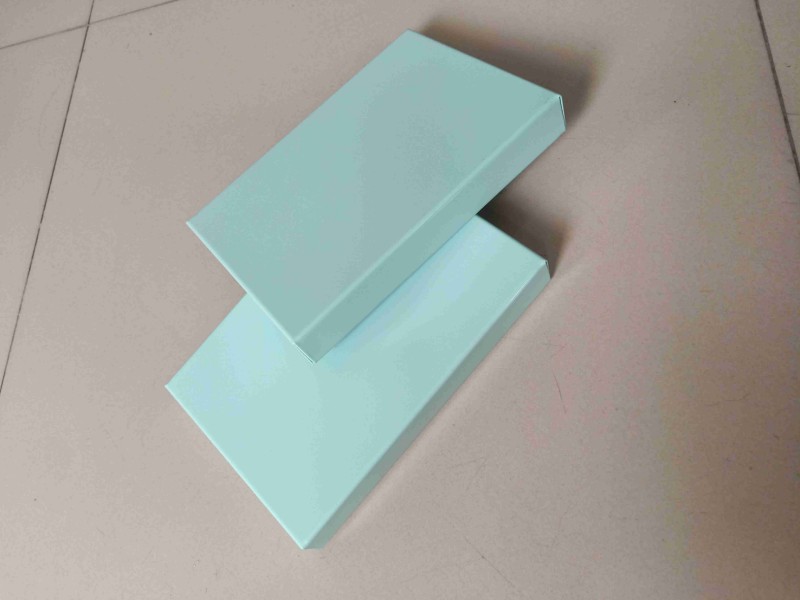

Custom sizes and colors are available.

Electrolytic steel plate for operating room

1. Introduction

In the highly demanding operating room environment, where strict hygiene, corrosion resistance and electromagnetic compatibility are critical, electrolytic steel plates have become the preferred construction material. These plates are designed to meet the specific requirements of such sensitive medical areas, ensuring the safety and success of surgical procedures.

2. Material characteristics

2.1 Surface quality

Smooth finish: Electrolytic steel plates used in operating rooms have an extremely smooth surface. The electrolytic process removes pollution and creates an uniform, mirror finish. This smoothness is very important, as it prevents the accumulation of dust, bacteria and other contaminants. In the operating room, even the smallest particle can potentially cause an infection, so the smooth surface of the steel plate allows you to easily clean and disinfect, supporting the sterile environment.

Antiadgesic properties: the surface of an electrolytic steel plate has inherent anti -adhesive characteristics. It is difficult to stick to bacteria and other microorganisms to the surface, which reduces the risk of biofilm formation. This property is crucial for the long -term maintenance of hygiene in the operating room, since biofilles can be a source of persistent infections.

2.2 corrosion resistance

Electrolytic coating: steel plates are covered with a thin layer of metal using an electrolytic process, usually zinc or zinc alloy. This coating acts as a sacrificial barrier, protecting the steel lying under it from corrosion. In the operating room where the environment can be exposed to moisture (from surgical procedures, cleaning agents, etc.) and various chemical disinfectants, corrosion resistance is of paramount importance. The electrolytic coating guarantees that the steel plate will remain intact and functional for a long period of time without risk of rusting or degradation, which may disturb the integrity of the design of the operating room.

2.3 mechanical strength

High rupture strength: electrolytic steel plates have a high tensile strength, which allows them to withstand mechanical loads associated with installation and use in the operating room. They can withstand the weight of the equipment, withstand hit in random clashes and maintain their structural integrity with normal wear in a loaded surgical environment. This strength is crucial for ensuring the safety of the operating room and its inhabitants.

3. Installation and integration

3.1 installation process

Precise installation: installation of electrolytic steel plates in the operating room requires accuracy. The plates are thoroughly measured and cut to the specific dimensions of the room. Then they are installed using specialized mounting systems, which provide reliable and dense landing. The joints between the plates are thoroughly sealed to prevent the appearance of gaps into which pollution could get. This precision installation process is performed by trained specialists to guarantee the preservation of the integrity of the hygienic environment of the operating room.

3.2 Integration with other systems

Electromagnetic compatibility: in modern operating rooms there is a wide range of electronic and medical equipment. Electrolytic steel plates are designed to be compatible with electromagnetic radiation. They do not interfere with the work of sensitive medical devices, such as MRI devices, X -ray equipment and electrocardiogram monitors (ECG). This compatibility is important for accurate diagnosis and treatment during surgical procedures, since any electromagnetic interference can lead to improper readings or equipment malfunctions.

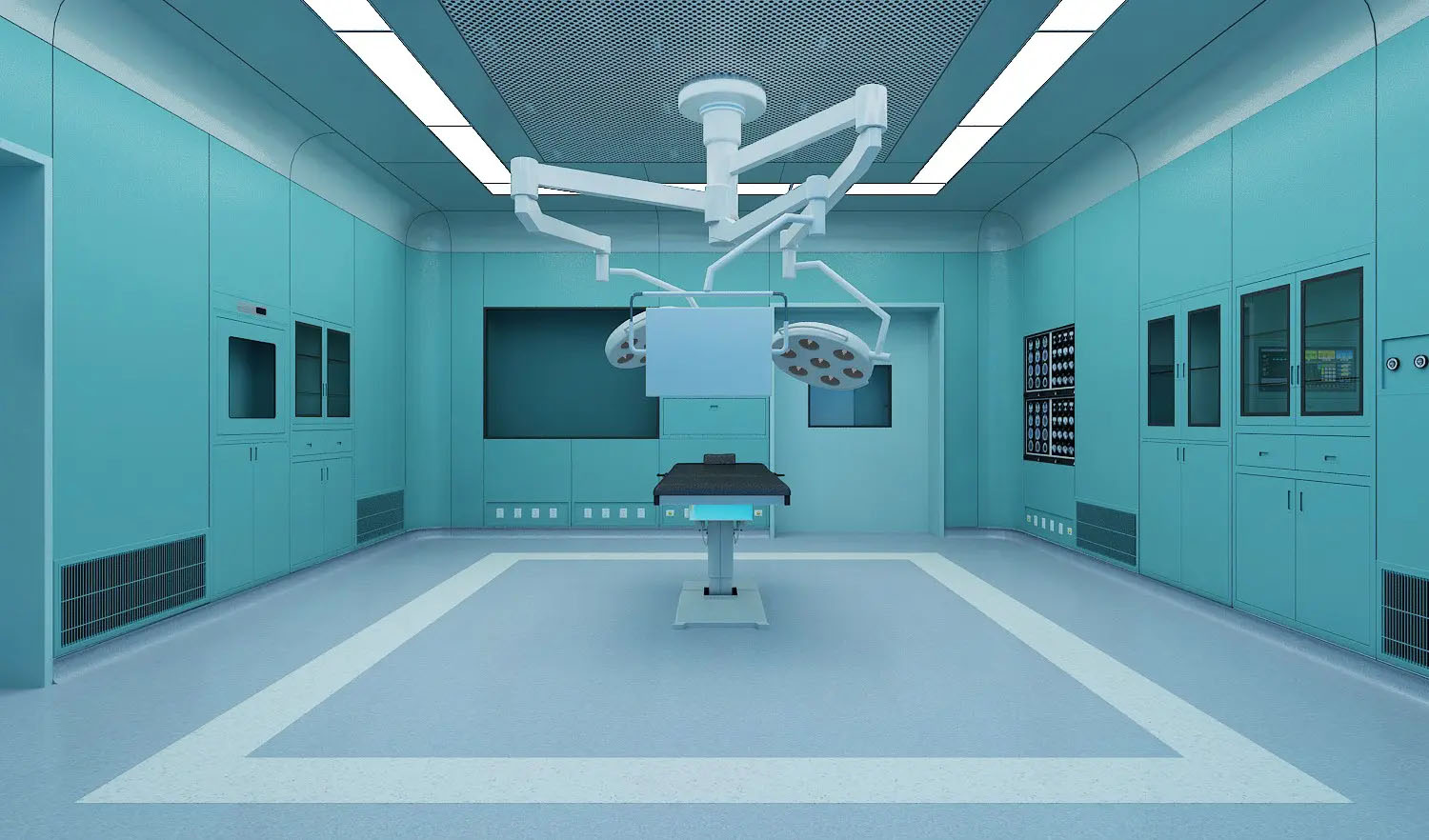

Integration with ventilation and lighting: steel plates are integrated into the ventilation and lighting systems of the operating room. The smooth surface of the plates allows you to easily mount ventilation ducts and lighting devices. The plates can also be designed in such a way as to effectively reflect light, improving the overall illumination in the operating room, while maintaining the environment without glare, which is crucial for surgeons performing delicate procedures.

4. Service and hygiene

4.1 cleaning

Easy to clean the surface: as mentioned earlier, the smooth surface of the plate made of electrolytic steel makes cleaning a simple process. Regular cleaning using soft detergents and disinfectants is sufficient to remove dirt, blood and other contaminants. The anti -adhesive properties of the surface also mean that less cleaning is required, which reduces the risk of surface damage and ensures the durability of the plate.

4.2 disinfection

Chemical resistance: electrolytic steel plate is highly resistant to a wide range of chemical disinfectants usually used in operating rooms. This allows you to carry out effective disinfection of the room between surgical procedures, killing any remaining bacteria, viruses or fungi. The stability of the plate to chemicals guarantees that the repeated disinfection cycles will not cause corrosion or degradation of the material, supporting the high level of hygiene standards of the operating room.

5. Application in the design of operating rooms

Construction of walls and ceilings

Hygienic barrier: electrolytic steel plates are usually used to build walls and ceilings of operating rooms. They act as a hygienic barrier, preventing the penetration of pollution from the outside. The smooth, seamless surface of the plates also gives the operating room a clean and modern appearance, which is not only aesthetically pleasant, but also psychologically comfortable for patients and medical personnel.