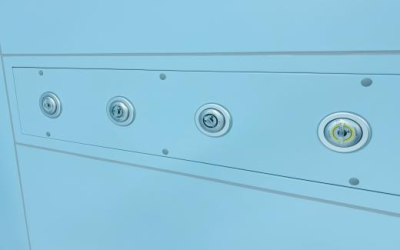

Double glazed insulated panel

Energy Efficiency: Maintains a stable indoor temperature and reduces HVAC costs

Hygienic: Smooth, sealed surface compatible with sterile cleaning

Silence: Significantly reduces noise transmission

Custom fit: Available in a variety of sizes and configurations

Cleanroom Durability: Resistant to chemical cleaners and contaminants

The double-glazed insulated panel is a high-performance architectural cleanroom solution designed for environments where strength, efficiency, cleanliness, and visible transparency are essential. Constructed of two panes of glass hermetically sealed with an air or inert gas layer between them, this insulated glass unit provides superior thermal and acoustic insulation.

It is an ideal choice for demanding environments such as hospitals, laboratories, electronic manufacturing, food processing areas and pharmaceutical cleanrooms where hygiene and climate control are critical.

Key Features

Excellent thermal insulation properties of glass

Double-layer sealed design with optional argon filling

Effective noise absorption, resistance to condensation

Custom sizes and thicknesses available

Strong and durable in controlled areas

Compatible with cleanroom wall systems and partitions

Optional coatings for UV protection and additional thermal insulation

Application

With its clean design and thermal stability, the Cleanroom Glass Panel is suitable for a wide range of industries and environments:

Hospitals and medical institutions:

Windows of intensive care units

Panels for isolation rooms

Medical equipment rooms

Laboratories and research centers:

Windows of microbiology laboratories

Biological safety partitions

Cleanroom monitoring panels

Pharmaceutical and food industry:

GMP cleanroom partitions

Sterile packaging zones

Food production windows

Electronics and semiconductor companies:

Dust-free clean room walls

Optical equipment laboratories

Antistatic closed environments

Technical Parameters

| Position | Characteristics |

| Glass structure | Double glazing (tempered optional) |

| Glass thickness | 4+9A+4 mm, 5+12A+5 mm (custom size) |

| Thermal insulation coefficient (U-factor) | ≤ 1.8 W/m²·K |

| Soundproofing | ≥ 35 dB |

| Frame compatibility | Modular wall systems for clean rooms |

| Coverage options | Low-E, anti-fog, UV coating |

| Application class | Cleanroom class 100–10000 |

Advantages

Energy Efficiency: Maintains a stable indoor temperature and reduces HVAC costs

Hygienic: Smooth, sealed surface compatible with sterile cleaning

Silence: Significantly reduces noise transmission

Custom fit: Available in a variety of sizes and configurations

Cleanroom Durability: Resistant to chemical cleaners and contaminants

Production process

Material selection (Highly transparent float glass)

Glass cutting and polishing

Installing the spacer frame and applying sealant

Gas filling (optional: Argon)

Edge sealing and frame integration

Thermal insulation, pressure and fog resistance testing

Packaging for international delivery

Quality Control Standards

Complies with ISO, GMP and EN12150 standards

Passed multi-point testing for fogging, leakage and optical clarity

Long-term moisture resistance and low thermal conductivity

Why choose us?

We specialize in high-quality cleanroom building materials and offer custom glass solutions to meet your project requirements. With our in-house manufacturing facility, experienced technical staff, and commitment to precision, we serve customers in the healthcare, biotechnology, semiconductor, and food industries worldwide.