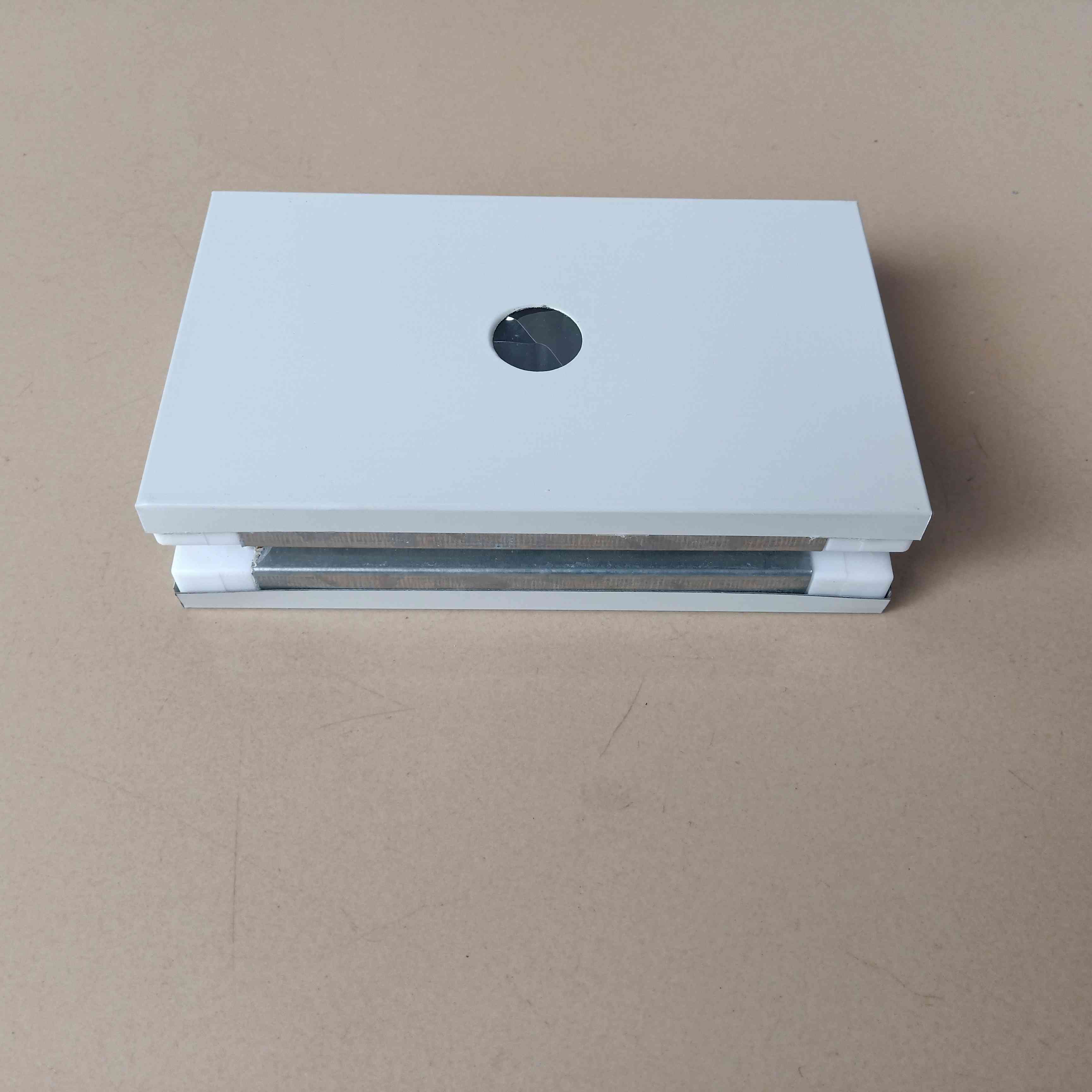

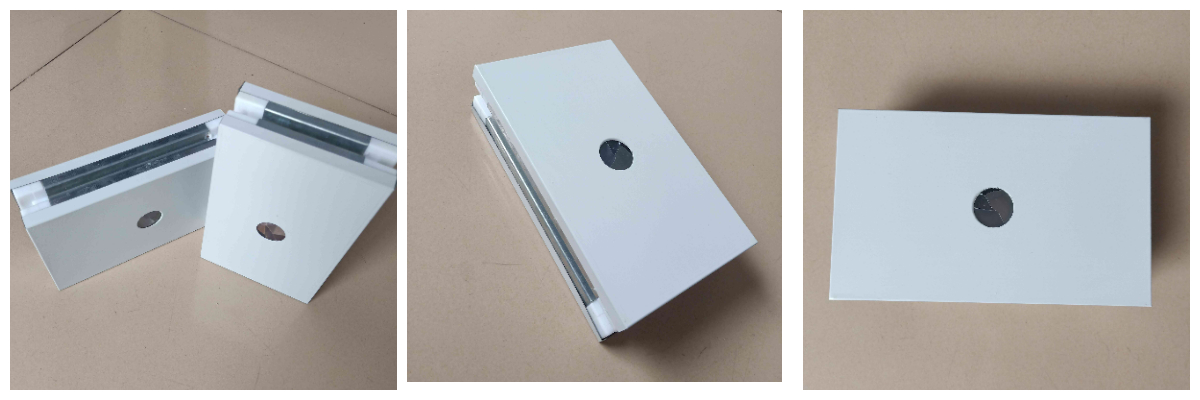

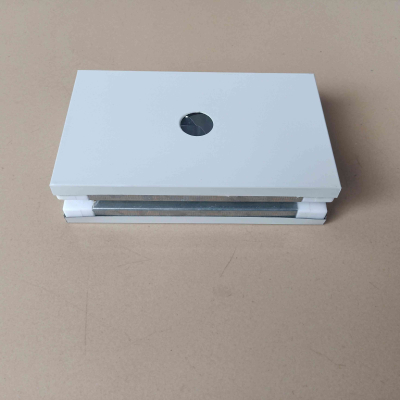

Handmade Aluminum Honeycomb Sandwich Panel

High strength and resistance to deformation

Light weight and easy to install

Excellent anti-corrosion properties

High level of tightness

Suitable for clean rooms (ISO cleanliness class 5-8)

Resistance to chemicals and antiseptics

Possibility of individual production according to drawings

Product description

Handmade sandwich panel with aluminum honeycomb core and painted steel— is a high-quality construction panel, handcrafted using an aluminum honeycomb core and a painted steel cladding. It provides excellent strength, lightness and high cleanliness indicators, making it an ideal solution for areas with increased requirements for sanitation and sterility.

Product details

The panel consists of three layers:

Outer layers: painted galvanized steel (color on request);

Inner layer: aluminum honeycomb core provides strength with light weight;

All elements are connected manually with high precision, which improves tightness and mechanical stability.

Various sizes, cladding thicknesses and honeycomb structure are available upon request.

Specifications

Panel thickness: 50mm / 75mm / 100 / 150mm

Steel thickness: 0.376-0.5mm

Filler type: aluminum honeycomb core

Density of aluminum honeycomb: 65–75 kg/m³

Fire resistance time:1-3 Hours

Thermal conductivity: ≤0.045 W/(m·K)

Soundproofing: up to 35 dB

Surface coating: polyester, PVC or antibacterial coating

Product benefits

High strength and resistance to deformation

Light weight and easy to install

Excellent anti-corrosion properties

High level of tightness

Suitable for clean rooms (ISO cleanliness class 5-8)

Resistance to chemicals and antiseptics

Possibility of individual production according to drawings

Applications

Cleanrooms in the electronics, pharmaceutical and food industries

Operating rooms and medical facilities in hospitals

Laboratories and research centers

Controlled production facilities

Aerospace and high-tech industry